Moist 3D printing filament

recognize in the blink of an eye

3D printing is and remains a megatrend. One of the most popular filaments is PLA, as it is very easy to process. However, this filament is very hydrophilic, i.e. it absorbs moisture easily if it is not stored dry. The same applies to the alternatives ABS and PA. In all cases, this can lead to undesirable effects in 3D printing.

3D printing is on the rise. The design possibilities seem endless, also thanks to the wide variety of different materials used. ABS and, above all, PLA are the most commonly used plastic filaments.

In this article you will learn:

- The differences between PLA and ABS and how they make themselves felt in 3D printing

- Which method is suitable for quickly checking filament for moisture and what limitations it entails

- You will learn how suitable this method is for PLA and ABS

- We answer the question of why moisture cannot be measured with black PA filament … and why it can with white PA filament

- You will receive further reading recommendations on the subject of PLA, PA & ABS filaments and how to store filaments in a dry place

- And some practical tips for measuring filaments

PLA vs. ABS - The differences

Polylactide, or PLA for short (from the English word “polylactic acid”), is a biodegradable plastic (biopolymer) that is made from renewable raw materials such as corn starch or sugar cane. Chemically speaking, PLA belongs to the polyester group.

Acrylonitrile butadiene styrene, or ABS for short, is an amorphous thermoplastic that is characterized by high strength values, good media resistance, high hardness and good scratch resistance.

This review article compares these two most commonly used filaments. What is missing, however, is the comparison of water absorption. However, due to the strong hydrophilicity (“water-loving”) of PLA, many users are confronted with a very annoying phenomenon. If the PLA filament is not stored properly dry, it will absorb water. This results in bubbles during printing, which can render the entire component unusable.

PA filament for 3D printing: strong, stiff and impact-resistant

For the more demanding user, the capabilities of PLA and ABS are soon no longer sufficient. A different filament is needed: PA is often the right choice here, as PA is characterized by

- Very high strength, stiffness and impact strength

- High abrasion and wear resistance due to good sliding properties

- Resistant to hydrocarbons, but also to alcohols, fats, esters and ketones.

- Very cold-stable, i.e. an application range: -70 °C to over 100 °C

PA is therefore suitable for use in highly stressed components such as gear wheels, hinges, rollers or bearing bushes.

How to quickly check filaments for moisture?

However, PA is just as delicate as PLA and ABS if it is not stored correctly. Open storage allows PA to absorb so much moisture that it may be unsuitable for further processing in 3D printing.

The same question arises in all 3 cases:

PA, PLA & ABS: How can the filament be tested for moisture before printing?

Near infrared spectroscopy (NIR) offers the possibility to distinguish “wet” from “dry” samples within seconds. Suitable databases with the corresponding references are used for this purpose.

NIR is an optical and, above all, very fast process. Until now, the technology has mainly been used in large, expensive and complex laboratory devices - and is therefore definitely not suitable for rapid testing in production directly on the 3D printer.

The Solid Scanner is a miniaturized NIR scanner with one-button operation and a user interface that focuses on the essentials. The scanner measures the reflection of the emitted light, with water being displayed at approx. 1,400 nm. “Dry” and “wet” samples of the same filament therefore only differ at this wavelength. The Solid Scanner provides the difference display, which shows the relative differences between the samples. New samples can therefore be assigned quickly.

The following series of measurements apply in each case:

- Moist filament = stored open for several days

- Dry filament = dried for 3 hours at 80°C in the oven

How to detect wet filament with NIR, using the example of PLA and ABS?

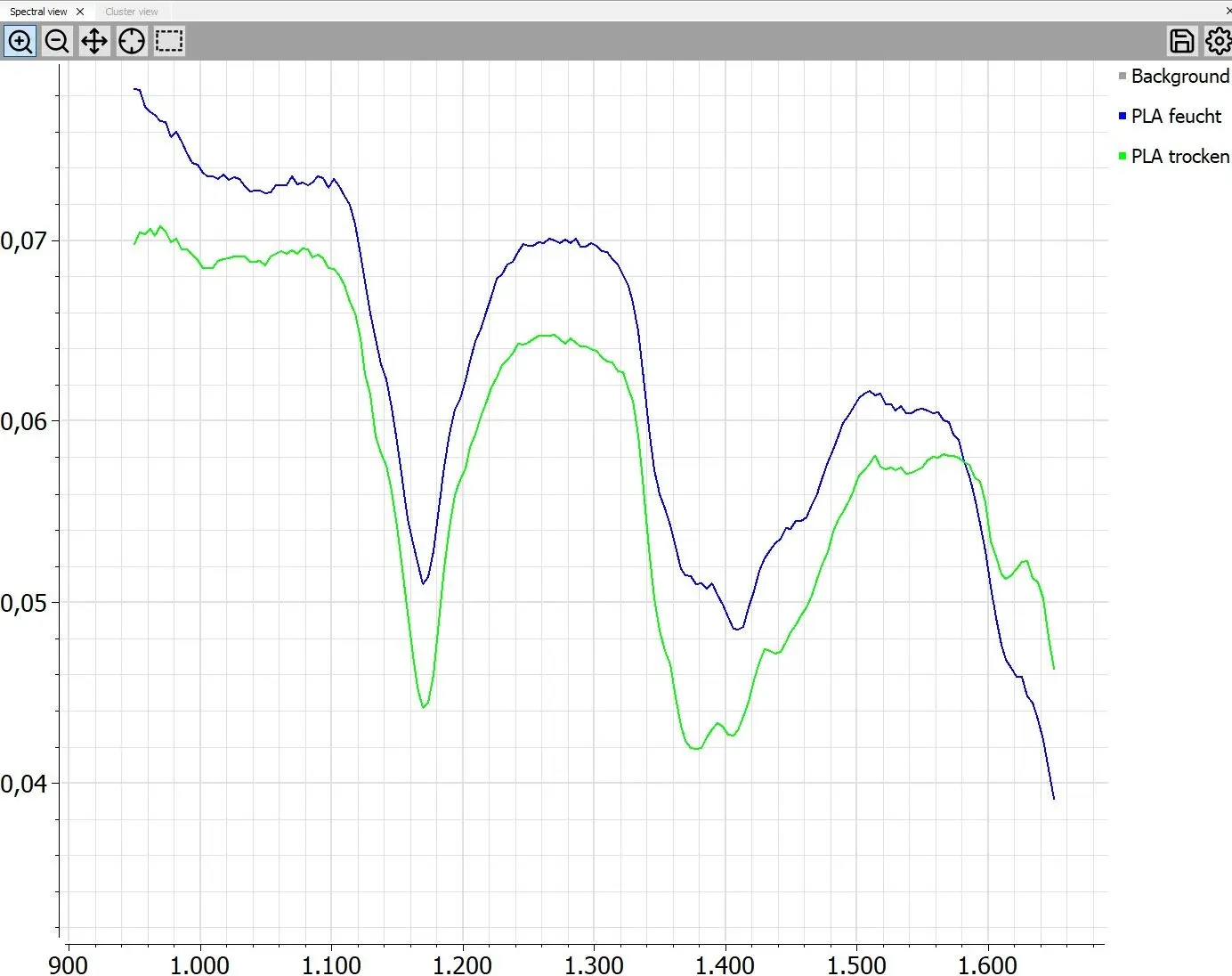

The NIR signal shows a clear difference in the raw spectra of the two PLA samples in the 1,400 nm range.

Due to the hydrophilic material properties, dry and wet PLA filament differ very clearly in the NIR spectra.

ABS is significantly less hydrophilic. This results in a smaller difference in the NIR signal. The smaller effect with ABS means that significantly smaller moisture differences can be reliably determined with PLA. NIR is therefore less suitable for ABS to distinguish wet from dry filament in this way.

How to detect wet filament with NIR, using the example of black PA and natural PA?

NIR is known for its inability to detect/measure black plastics. Put simply, the entire NIR signal is absorbed in the range from 900 nm to 1,700 nm; the spectrometer receives no more than a signal noise.

Nevertheless, we were repeatedly confronted with the question of whether one could not at least see differences in moisture in black PA, as the example of PLA shows that the “moisture signal” is very dominant. The NIR spectra of black PLA and white PLA are as follows:

A typical NIR signal for black plastics (below): very high absorption and a “noisy” measurement signal without relevant peaks. In direct comparison, the NIR spectra of white PA.

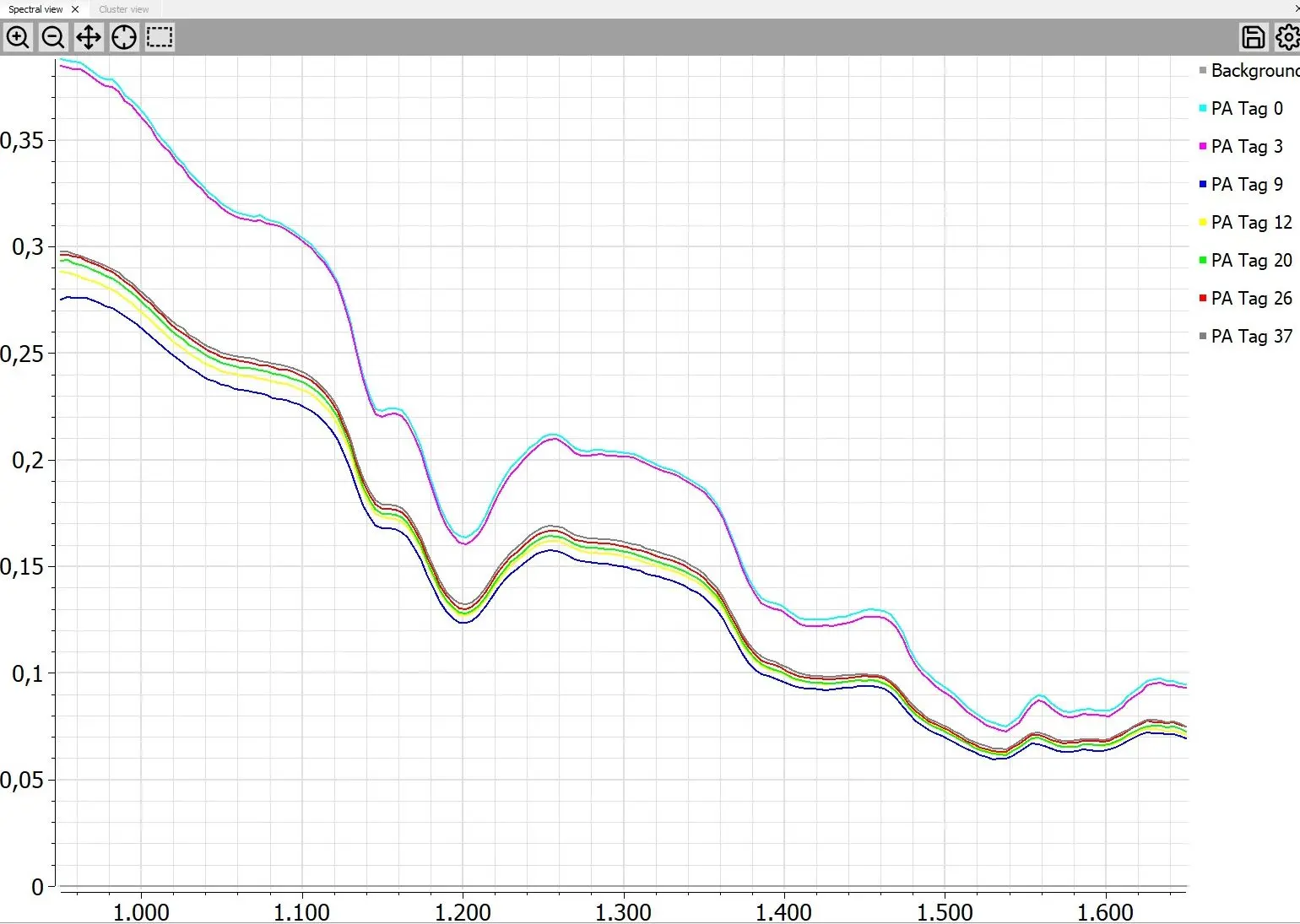

The noisy signal with black PA does not lead to any significant differences, not even at 1,400 nm despite the existing differences in humidity. With PA nature, the NIR signal looks fundamentally different:

A typical, good NIR signal: PA nature is much better suited for NIR.

The graph above shows the NIR signals after the filament has been stored open for the specified days. There is a clear jump between day 3 and day 9. It turns out that the filament can apparently be stored open for several days without any loss of quality.

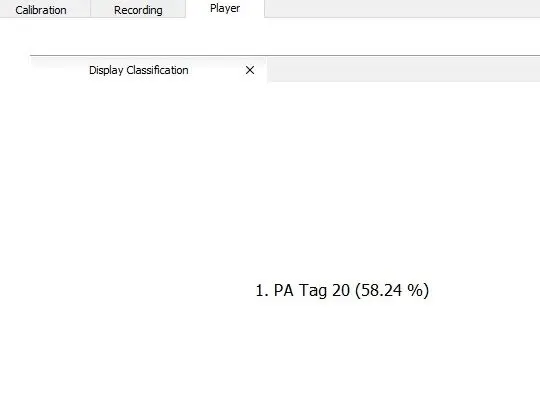

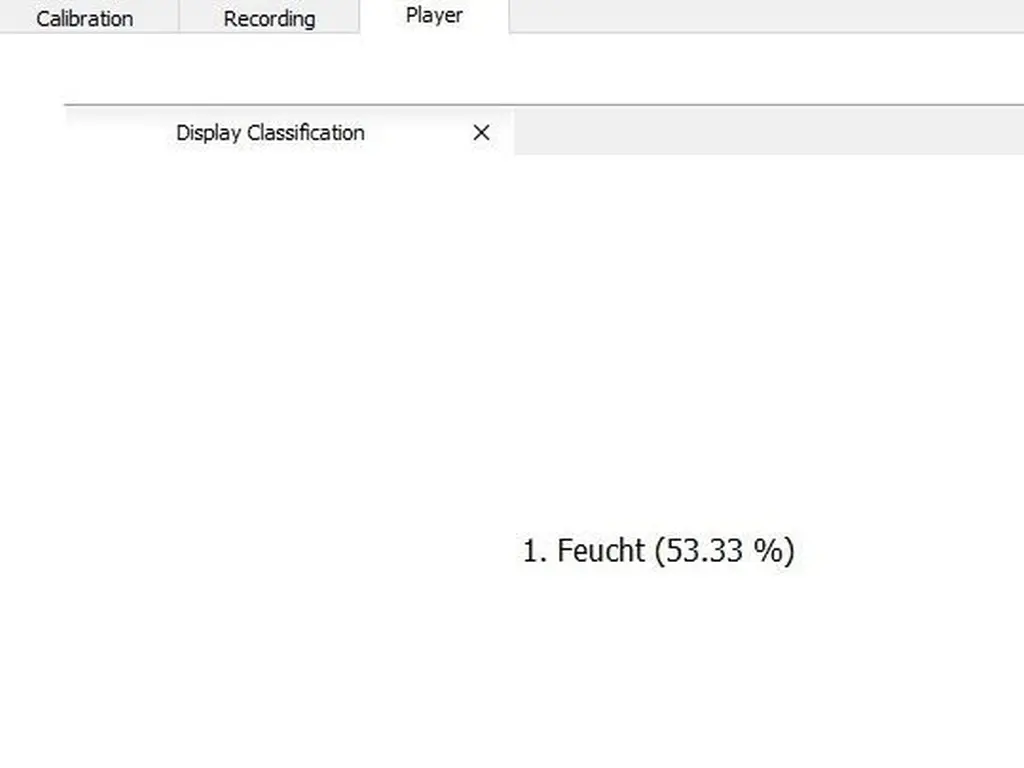

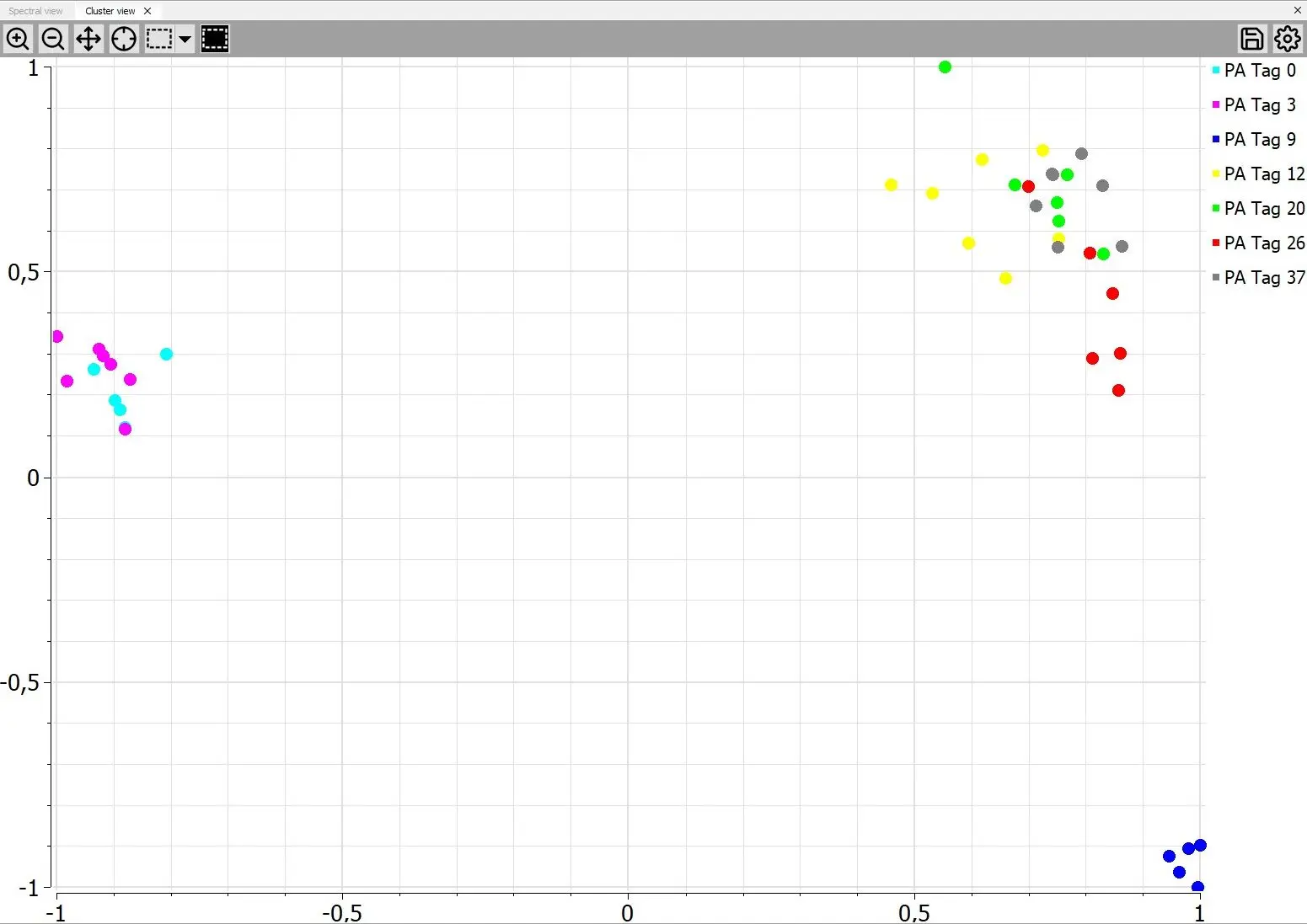

Our software suite offers machine learning methods to search for patterns in this data. These spectra can be easily separated:

Using machine learning methods, they can clearly separate the spectra into two groups.

As expected, dry and wet 3D printing filament made of natural PA can be distinguished very well with NIR. Based on this data, specific applications can be generated:

In the example on the left, all measurements were taught in as individual groups; in the example on the right, measurements were combined in a meaningful way.

In the example on the left, the match is displayed as “(moisture on) day 20”. The new measurement is therefore most similar to the reference measurement from day 20. In the example on the right, only the information “Wet” or “Dry” is output according to the combined groups. A pragmatic decision for day-to-day operations.

Determining the moisture content of a filament with the Solid Scanner is quick and easy.

Tips for daily operational use

- Thanks to its compact size and simple operation, the Solid Scanner is suitable for use directly on the 3D printer by non-professionals.

- To determine the moisture, the filament is placed directly on the scanner. The examples shown are each approx. 1 mm thick filament.

- We recommend teaching in your samples for your own application. This is quick and easy to do and is therefore perfectly tailored to your requirements. You should always know when your filament is “too wet” or “dry enough” for your application. These two groups are then stored as references. When checking a new filament, the result is then compared with these two references.

Recommendations

- NIR is better suited for detecting moisture in the filament for PLA than for ABS

- NIR is not suitable for soot-colored, i.e. black, filaments