Is My 3D Printing Filament Dry?

How to Detect Moisture in PLA, ABS, PA (Nylon) and More – And Why NIR Might Be the Future

So how can you know if your filament is dry? And could NIR (Near-Infrared) spectroscopy offer a better way to test it? Let’s dive into what’s currently possible, what’s not, and where the industry might be headed.

Why Filament Moisture Matters

Most popular 3D filaments - like PLA, ABS, PETG, and especially PA (nylon) - are hygroscopic. That means they absorb water from the air. Even small amounts of moisture can cause:

- Steam bubbles and stringing

- Weakened part strength

- Poor layer adhesion

- Inconsistent extrusion and nozzle jams

The effects are especially severe with nylon, TPU, and PC. But even “low-risk” materials like PLA can suffer under the wrong conditions.

How Can You Tell if Filament Is Wet?

Reliable DIY methods:

- Visual test: Watch for steam or popping at the nozzle.

- Weight check: Compare to known dry weight (if available).

- Print test: Print a test cube and inspect surface quality.

- Drying + comparison: Dry the filament, reprint, and compare results.

External resources:

- How to Dry Filament (All3DP)

- Filament Drying Temps (Prusa Knowledge Base)

- DIY Filament Drying Box (Hackster)

What About NIR (Near-Infrared) Spectroscopy?

This is where it gets interesting.

NIR spectroscopy can detect water content in polymers - scientific literature and industrial setups prove it. The idea is simple: water absorbs specific NIR wavelengths, and that shows up as changes in the spectral fingerprint.

But here’s the catch…

While NIR is a powerful tool in lab and factory settings, it’s currently not a cost-effective or reliable method for measuring filament moisture in small-scale environments.

Here’s why:

- Precision: The moisture signal is subtle and varies by polymer.

- Calibration: You’d need different models for each material type.

- Surface effects: Dust, colorants, and extrusion irregularities can distort readings.

- Cost: Lab-grade NIR sensors cost several thousand euros.

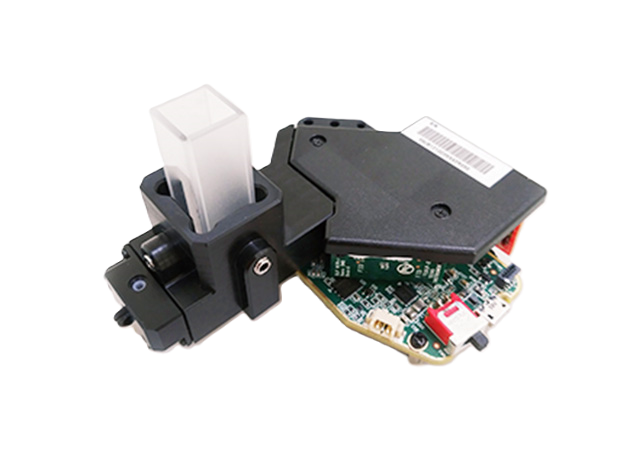

At Solid Scanner, we offer advanced NIR tools like the Avenir Photonics Siena spectrometer - but they’re primarily used in recycling, R&D, and quality control, not filament testing … yet.

What’s the Future of Filament Testing?

We believe a more accurate, handheld test for filament dryness will eventually be possible - maybe even based on NIR. We’re watching this space closely.

If you’re a researcher, filament producer, or 3D printing innovator working on this challenge, let’s talk. We’re happy to explore pilot tests or partnerships.

What Can You Do Today?

Until affordable sensors catch up, here’s your best approach:

- Always store filament in airtight containers with desiccants

- Use a filament dryer or dehydrator (50 - 70°C for PLA, up to 80 - 100°C for nylon)

- Weigh and document spools over time

- Don’t trust “fresh out of the bag” - many spools are already partially wet

Helpful products:

Bottom Line

Yes, filament moisture is a real problem. But no, there isn’t a foolproof, affordable sensor - yet.

We’re not going to sell you a false promise. But we will keep exploring how advanced spectroscopy can solve real problems for real people - whether you’re sorting plastics or pushing the limits of 3D printing.

Want to stay informed about NIR and materials tech?

📩 Join our mailing list (see bottom of this page) for industry tips, use cases, and honest insights.