PVC: Distinguishing between very similar raw materials - the example of Vinnolit and Neralit

PVC is a basic material for many products and correspondingly many manufacturers offer the same material. Nevertheless, it is necessary to be able to distinguish between raw materials from different manufacturers in the incoming goods inspection. The companies Vinnolit and Unipetrol are two major manufacturers. They sell the Vinnolit and Neralit brands. These two examples are used here to show how differentiation is achieved using NIR.

NIR for quick and easy QA of PVC

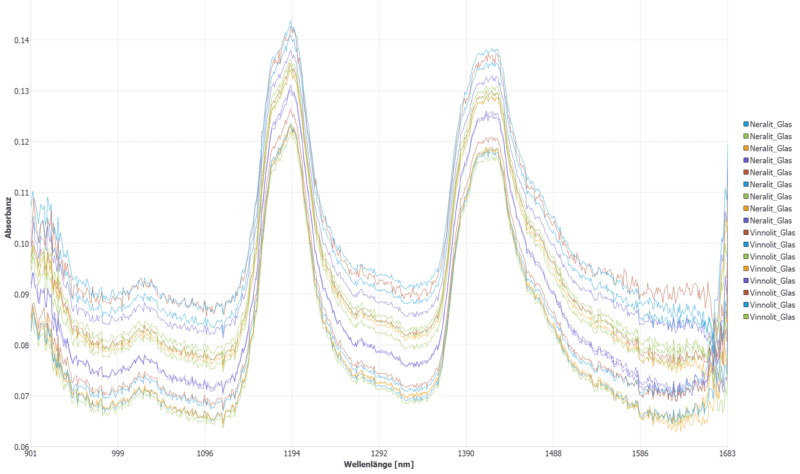

Near-infrared spectroscopy (NIR) is a proven optical method known for its simplicity and speed. The Solid Scanner - a fist-sized NIR spectrometer used for this test - is a latest-generation NIR scanner with a focus on ease of use. A scan takes approx. 5 seconds, the typical NIR spectrum of PVC looks as follows:

Due to the strong similarity of the samples, no differences can be recognized in this representation. With these fingerprints, however, PVC can be reliably distinguished from other substances.

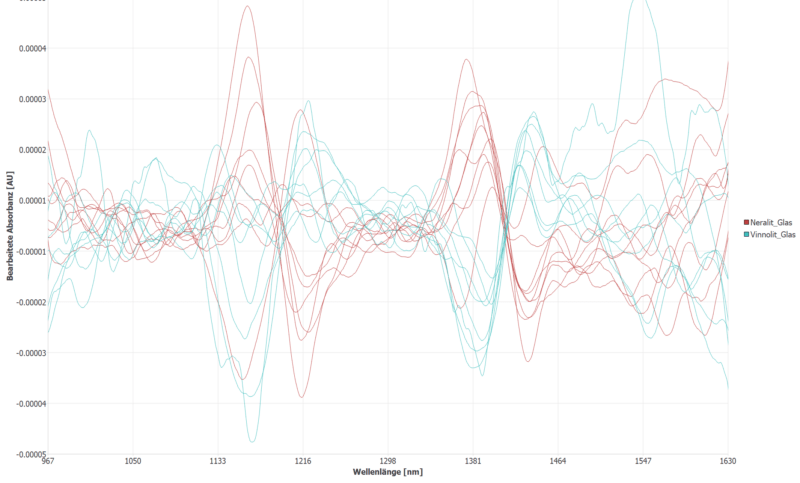

Difference diagram shows the smallest differences between Vinnolit & Neralit

The difference display, on the other hand, shows the real differences between the samples at each individual wavelength in detail. There are very small but clear differences at 1,380 nm and 1,420 nm. The low values in the “processed absorbance” (Y-axis) are a good indication of the low absolute differences in the sample and thus of the high resolution and precision of the scanner.

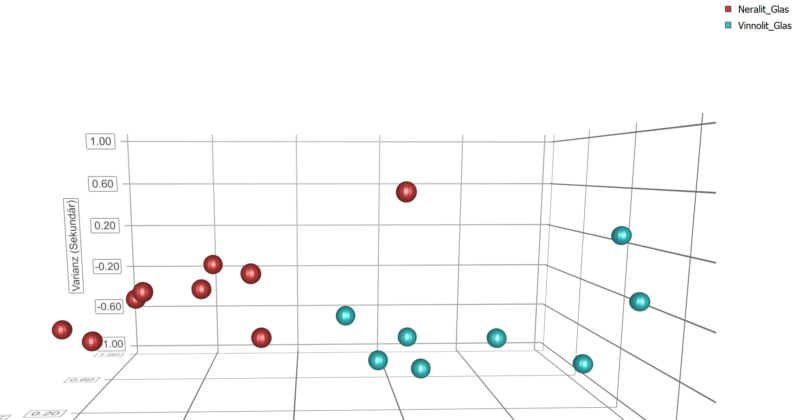

Cluster display clearly groups many measurements of the PVC samples

In the cluster display, the differences in the spectra are added up and displayed as a single value. Spectra that hardly differ are spatially close to each other.

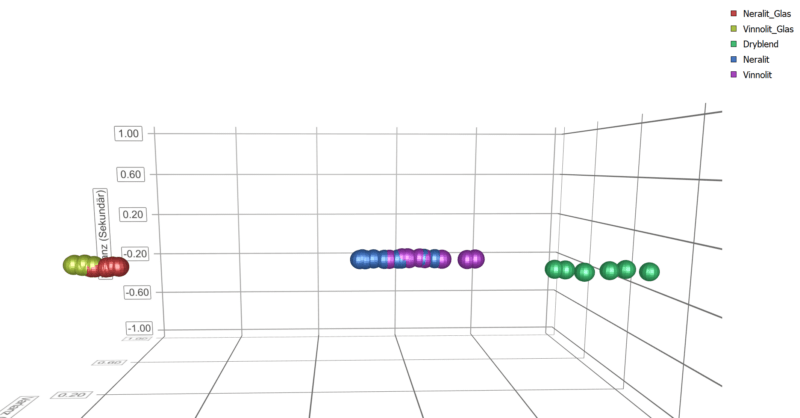

Since the samples - as seen in the difference plot - only differ significantly at a few points in the NIR spectrum, the different clusters overlap. Measurements in the bag, in the preparation jar and dryblend If the measurements in a (plastic) bag are added (in blue/purple), it can be seen that the bag leads to stronger variances and the clusters overlap more or are more difficult to distinguish. Measuring the PVC in preparation jars is therefore highly recommended. If a dryblend is also included (in green; PVC with various stabilizers), it becomes apparent that the differences detected between Vinnolit and Neralit are very slight.

The cluster display with a dryblend shows how small the absolute differences between the two PVC samples are.

Conclusion: Despite great similarity, Vinnolit and Neralit can be distinguished

Despite the slight differences between these standard raw materials, Vinnolit and Neralit can be distinguished in the NIR spectrum. However, the samples should be measured in preparation vials. This preliminary work is not necessary for differentiation from other substances, e.g. dryblends.

Test setup NIR measurement

The hardware used for this test was

Software

Accessories

- Preparation jars (please enquire directly)