Handheld near infrared spectrometer

New sensor technology allows compact, cost-effective design & easy operation

The easy-to-use NIR scanner, hardly larger than a standard computer mouse, is used both inside and outside laboratories, e.g. in incoming goods or production. The Solid Scanner explicitly dispenses with many setting options and instead offers the essential functions that are controlled with a button.

This way you can create a spectrum of the desired material in less than 1 second and immediately make a statement about the type and quality of the material. The Solid Scanner serves you as a mini-laboratory and is in many cases a simple and inexpensive solution for laboratories entering the world of NIR spectroscopy.

The working principle

The scanning process is either started with the only available button on the scanner itself, or by a software button on the computer. Thereby, the NIR scanner measures an area of 3 x 3 mm and in case of non-transparent (plastic) materials up to a depth of 0.2 mm up to 0.3 mm, in case of transparent materials accordingly deeper. The generated spectrum is an average value of the chemical composition of this material.

In this way, coatings on materials can also be detected and differentiated. From a layer thickness of approx. 50 µm to 100 µm, differences in the NIR spectrum become visible.

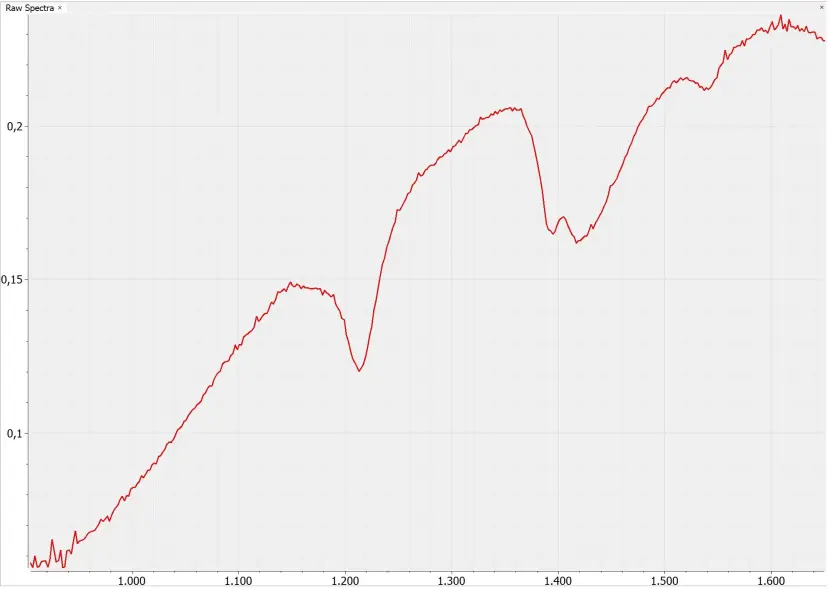

Visualization of NIR spectra from 900 nm to 1,700 nm by absorbance.

Available options

The scope of delivery of the scanner includes our software solution with the software base module for generation, visualisation and storage of NIR spectra. It enables experts to identify plastics by interpreting the measured spectrum. However, no expert knowledge is necessary to use the Solid Scanner to identify materials.

On this technological basis, we offer the use of various (prefabricated) “applications”:

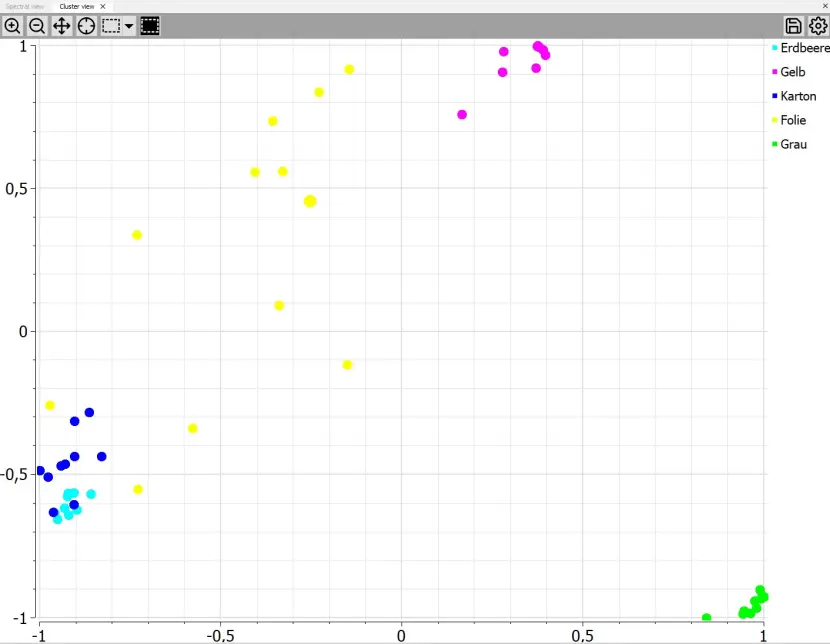

- Standard analysis: grouping spectra together. This enables them to recognise correlations in large amounts of data. You can teach in different groups and then create your own application from them. A classic application example for this is the incoming goods inspection.

- Standard applications – applications that we have developed for specific tasks. Examples of this:

- Plastics database – identification of plastics based on our references.

- NIR detectability – enables the quantitative determination of a NIR signal in direct comparison to a reference signal.

- Individual applications

If you need an individual solution for your task, we can develop almost any complex application for you.

The cluster analysis clearly shows similar spectra in groups. There are very homogeneous groups with little variation in the NIR signal (e.g. green group), but also groups with high variation (e.g. yellow group).

Applications for a handheld NIR scanner

This makes the Solid Scanner an indispensable tool for the fast and reliable determination of batch variations, the initial assessment of damage cases, competition analysis or the sorting of production waste by type.

- Plastics consultants, engineering service providers and testing service providers use the compact scanner to prepare specifications and expert reports.

- Laboratory managers, on the other hand, appreciate the advantages for quick material analysis.

- Quality managers and production managers, on the other hand, check curing processes for epoxy resins or the correct allocation of materials in the warehouse in random samples.

Limitations

- Inline measurements are only limited possible due to the measurement duration of 500 ms

- The following materials cannot be measured, or only with severe limitations:

- Plastics coloured with carbon black absorb large parts of the light impulse. In such cases, the measurement duration must be set considerably higher. The measurement of very dark or black plastics is therefore not possible. If the black coloration is produced without carbon black – for example by combining different color pigments – measurement with NIR is possible without restrictions.

- Metals

- Inorganic powders, such as pure titanium dioxide If titanium dioxide is used as filler, it weakens the signal. Thus, white coloured PVC plastics with different filler contents are distinguished.