Rapid test Material testing

in goods receipt

The forwarding agent in the delivery department cannot wait for the result from the laboratory, even if the processes in the incoming goods department have already been optimized in terms of time. It is hoped that fluctuations in the quality of new deliveries can be avoided. But if problems do occur, the annoyance is twice as great: not only does the missing product stop production, it also has to be removed from the warehouse or silo. Rapid tests in the incoming goods department provide a replacement, enabling on-site inspection at the moment of delivery.

Point of Care

In the medical field, these on-site tests are also called “point of care”, where the patient is at the moment and you cannot and do not want to wait for the results from the laboratory. Simple blood tests, instead of complex laboratory tests, are an example of common tests in this area.

Infrared spectroscopy in incoming goods

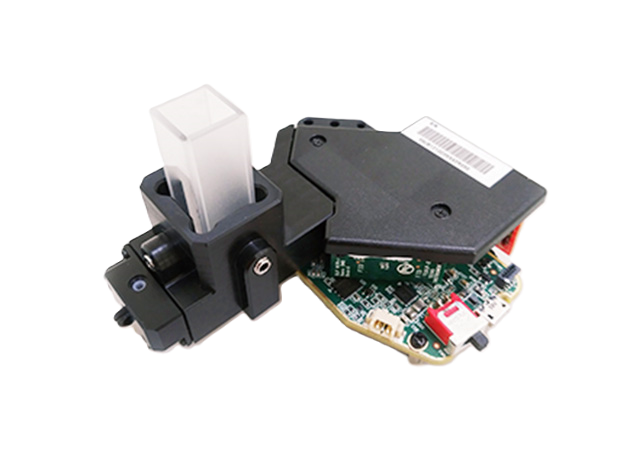

There are various technological approaches to meet these requirements. (Near) infrared technology (NIR) has established itself in the handling of plastics. NIR is known as a proven and fast technology for material testing. The latest generation of NIR hand-held scanners are very fast, easy to use, only the size of a fist and inexpensive. They are therefore very well suited for use in incoming goods.

Material testing with spectral analysis

In infrared spectroscopy, the material to be examined is irradiated with broadband light. Depending on the chemical composition of the material, certain wavelengths of light are absorbed and others reflected. The resulting image is called a spectrum. It works like a fingerprint: there are characteristic and unique fingerprints for each material.

Experts are able to assign the functional groups on the basis of the peaks in the spectrum and can thus determine or at least preselect materials without further aids. However, this method is just as suitable for laypersons, as the analysis of the spectra can be bypassed.

If a database with the “fingerprints” of various materials is available, the scanner itself can recognize whether the measured material corresponds to a material from the reference database or not. This assignment succeeds in seconds and thus the identification of the materials.

Reference data can be obtained from us or simply generated yourself. The operating concept of the Solid Scanner also allows non-experts to teach in new references or extend existing references.

Advantages

- A measurement with this scanning method usually takes less than a second. The rapid availability of the results means that conclusions can be drawn immediately.

- Furthermore, there is of course no need for transportation to the laboratory and you do not have to take into account the time schedules in the laboratory.

- The fist-sized scanner offers the same precision as table-sized laboratory devices, but does without some convenient functions.

How is NIR used in incoming goods?

- Monitoring of quality fluctuations, e.g. water absorption of granulates

- Accurate differentiation of individual plastics, e.g. differentiation between PA6 and PA66

- Verification of varietal purity, e.g. in recycling

Restrictions

Measuring devices only pass the practical test in incoming goods if they are equally easy to use, robust, fast and inexpensive to purchase. All of this applies to the Solid Scanner, but there are some fundamental limitations to NIR technology:

- scanner works with a wavelength of 900 nm to 1,700 nm, which is why not all materials can be detected.

- Carbon black colored plastics

However, please discuss your application with us in detail in advance. This is the only way we can determine whether the Solid Scanner is the right solution and whether the restrictions are actually relevant for you. We are happy to provide tips and tricks and help with advice on the correct preparation of the rehearsals to ensure a smooth operation.