Understanding Near-Infrared Spectroscopy (NIR):

A Comprehensive Guide to Wavelength Ranges and Applications

A Comprehensive Guide to Wavelength Ranges and Applications

Introduction

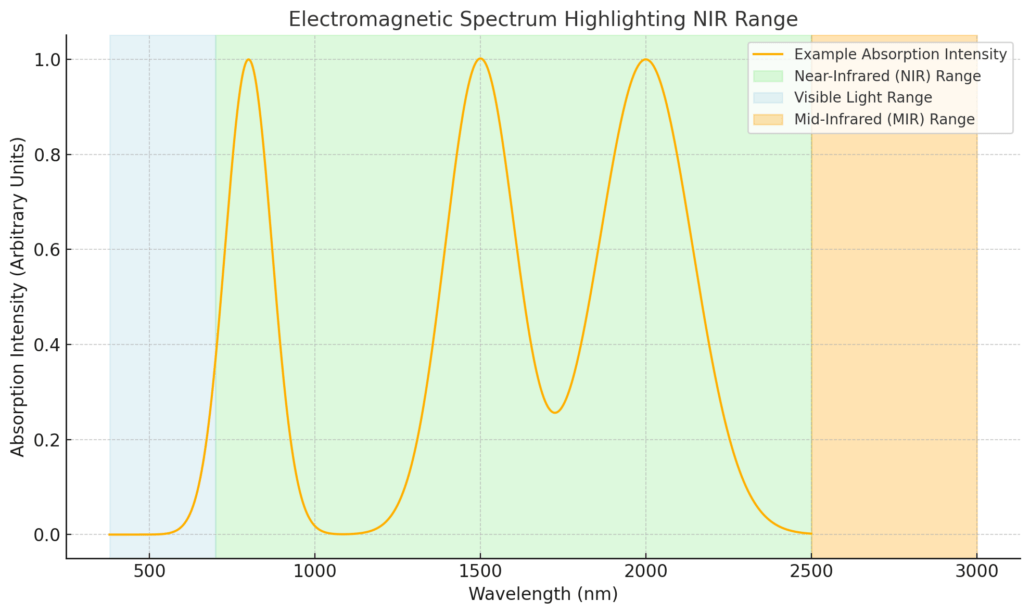

Near-Infrared Spectroscopy (NIR) is a powerful and versatile analytical tool utilized across diverse industries to analyze material composition. Covering a spectral range from approximately 700 nm to 2500 nm, NIR spectroscopy offers rapid, non-destructive, and highly accurate measurements. This makes it indispensable in applications such as plastics recycling, food quality control, pharmaceutical manufacturing, and agricultural monitoring.

This guide explores the fundamentals of NIR technology, highlights its applications across industries, and provides a framework for selecting the appropriate spectrometer for specific tasks.

Basics of NIR Spectroscopy

The Science Behind NIR

NIR spectroscopy is based on the absorption of near-infrared light by molecular bonds such as O-H, N-H, and C-H. When NIR light interacts with a material, specific wavelengths are absorbed depending on the molecular composition, while others are reflected or transmitted. The resulting spectral data represent the material’s unique “fingerprint,” which can be analyzed to determine its composition.

Key characteristics of NIR include:

- Speed: Real-time measurements enable quick decision-making.

- Non-Destructive Analysis: No sample preparation or alteration is required.

- Portability: Modern spectrometers are compact and suitable for field applications.

Wavelength Ranges and Their Applications

NIR operates across various spectral ranges, each suited to specific analytical tasks:

- 900 nm - 1700 nm: Ideal for detecting moisture, distinguishing organic compounds, and basic material identification.

- 1350 nm - 2150 nm: Effective for plastics differentiation and molecular specificity in complex materials.

- 1600 nm - 2400 nm: Suitable for advanced material characterization, including high-performance polymers and pharmaceutical ingredients.

External Resources

For further exploration into NIR spectroscopy and its applications, consider these resources:

- Spectral Analysis and Applications - Oxford Instruments: Insights into wavelength ranges and their industrial uses.

Applications Across Industries

Plastics Recycling

NIR spectroscopy has revolutionized plastics recycling by enabling accurate, efficient material identification and sorting. Each polymer type exhibits unique spectral characteristics, making NIR an essential tool for:

- Identification of PA6 vs. PA66 (Nylon)

- Best Range: 1350 nm - 2150 nm

- Reason: Both are polyamides used in fibers, but differ in their melting points and molecular structure, which NIR can detect.

- Use Case: Ensures material quality in manufacturing for automotive and textile applications.

- Moisture Content in Plastics

- Best Range: 900 nm - 1700 nm

- Reason: NIR can accurately measure water content, crucial for ensuring the integrity of plastics used in 3D printing and other precision molding processes.

- Use Case: Recent studies show how NIR spectrometers reduce defective 3D filaments by tracking moisture levels in real-time.

- Differentiating PMMA (Acrylic) vs. PC (Polycarbonate)

- Best Range: 1600 nm - 2400 nm

- Reason: PMMA and PC are often used in optics and medical devices, but their thermal properties differ significantly. NIR helps distinguish between them efficiently.

- Use Case: Ensures precise sorting in recycling plants for higher yield and quality.

- Detecting TiO2 Content in Plastics

- Best Range: 1600 nm - 2400 nm

- Reason: TiO2 is a common filler in plastics and coatings. NIR can assess its concentration, which affects the material’s opacity and durability.

- Use Case: Widely used in quality control for packaging materials.

Limitations in Plastics Recycling

While NIR is effective for most plastics, it struggles to analyze carbon black-filled plastics due to the absorption characteristics of the black pigment. This remains a significant challenge in the recycling industry, but emerging technologies are working toward solutions.

Food and Agriculture

Food & Agriculture: Monitoring Quality & Freshness with NIR

NIR spectrometers are used extensively in the food and agricultural sectors to monitor quality parameters like sugar content, moisture levels, and ripeness, ensuring product consistency and safety.

Common Tasks & Best Wavelength Ranges:

- Measuring Sugar Content in Apples

- Best Range: 900 nm - 1700 nm

- Reason: This range captures the vibrational overtone of sugars, enabling fast and accurate assessments.

- Use Case: A recent bachelor thesis demonstrated how our NIR spectrometers accurately measured sugar content, ensuring optimal harvesting time.

- Ripeness of Strawberries

- Best Range: 900 nm - 1700 nm

- Reason: NIR can non-invasively monitor anthocyanins and other compounds responsible for color and ripeness.

- Use Case: Enables farmers and suppliers to optimize storage and transport conditions, reducing spoilage.

- Moisture Content in Grains

- Best Range: 900 nm - 1700 nm

- Reason: Water molecules have strong absorption peaks in this range, making it ideal for rapid moisture analysis in grains like wheat and corn.

- Use Case: Ensures that grains meet regulatory standards for dryness, avoiding spoilage and mycotoxin formation.

Pharmaceuticals

The pharmaceutical industry relies heavily on NIR technology for in-line quality control during production, ensuring that tablets and powders meet the required specifications.

Common Tasks & Best Wavelength Ranges:

- Active Pharmaceutical Ingredient (API) Concentration

- Best Range: 1350 nm - 2150 nm

- Reason: NIR is used to assess API content in both solid and liquid formulations, ensuring uniformity and dosage accuracy.

- Use Case: Real-time monitoring during tablet production prevents costly batch rejections.

- Moisture Content in Powders

- Best Range: 900 nm - 1700 nm

- Reason: Ensuring proper moisture content is critical to prevent degradation or uneven mixing in powders.

- Use Case: Pharmaceutical companies use NIR to maintain product stability and shelf life.

Selecting the Right NIR Spectrometer

Choosing the appropriate spectrometer involves evaluating your specific application requirements. Consider the following factors:

Key Parameters

- Wavelength Range: Match the range to your analytical needs (e.g., moisture detection vs. polymer analysis).

- Resolution: Ensure the device can distinguish subtle spectral differences.

- Ease of Use: Look for intuitive software and pre-configured libraries for specific applications.

Our Portfolio - Overview

- trinamiX

- Portable devices with integrated material libraries.

- Ideal for plastics recycling and field applications.

- Inno Spectra

- Advanced DLP sensor technology for high-precision measurements.

- Suitable for industrial and laboratory use.

- Avenir Photonics

- Cutting-edge spectrometers with a wide wavelength range (900 nm - 2100 nm).

- Designed for demanding research and development tasks.

Conclusion

Near-Infrared Spectroscopy is an indispensable technology for industries requiring rapid, accurate, and non-destructive material analysis. Whether you’re in plastics recycling, food production, or pharmaceuticals, the right NIR spectrometer can streamline operations and improve outcomes. Explore our comprehensive portfolio to find a solution tailored to your needs.

Contact us today to schedule a demonstration.

About us – Solid Scanner

Let’s take responsibility and recycle more plastics, textiles, carpets, mattresses and more – ask us for suitable solutions. Our portfolio includes solutions ranging from small, portable solutions to individual solutions based on hyperspectral camera systems for simple, automated identification of plastics and in the sorting process and for inline process control, e.g. for homogeneity.

About trinamiX – the sensor technology company

Our technology partner trinamiX GmbH, based in Ludwigshafen, was founded in 2015 as a wholly owned subsidiary of BASF SE. As a start-up within the company, it is not only operationally independent, but also has unique access to the expertise and experience of the entire BASF Group. Its patent-pending technologies enable people and machines to capture the hidden and invisible world around them to make better decisions and increase safety.