Detectability and recyclability of adhesive tapes are becoming key concerns for manufacturers, recyclers, and product designers alike. As European waste regulations tighten, pressure is increasing on producers to ensure their tapes can be properly sorted and do not disrupt downstream recycling processes.

At Solid Scanner, we offer practical, low-barrier solutions to help small and medium-sized enterprises (SMEs) test their materials — without needing a laboratory setup.

Challenge 1: PVC-Based Adhesive Tapes in Waste Management

In many EU countries, PVC must be sorted out before incineration due to hazardous by-products. However, manually detecting PVC-based tapes and films is often challenging for recyclers.

Our Solution

Using our portable NIR scanner, recyclers and manufacturers can test in seconds whether a tape is PVC-based — or made from other common materials like PP, PE, or PET.

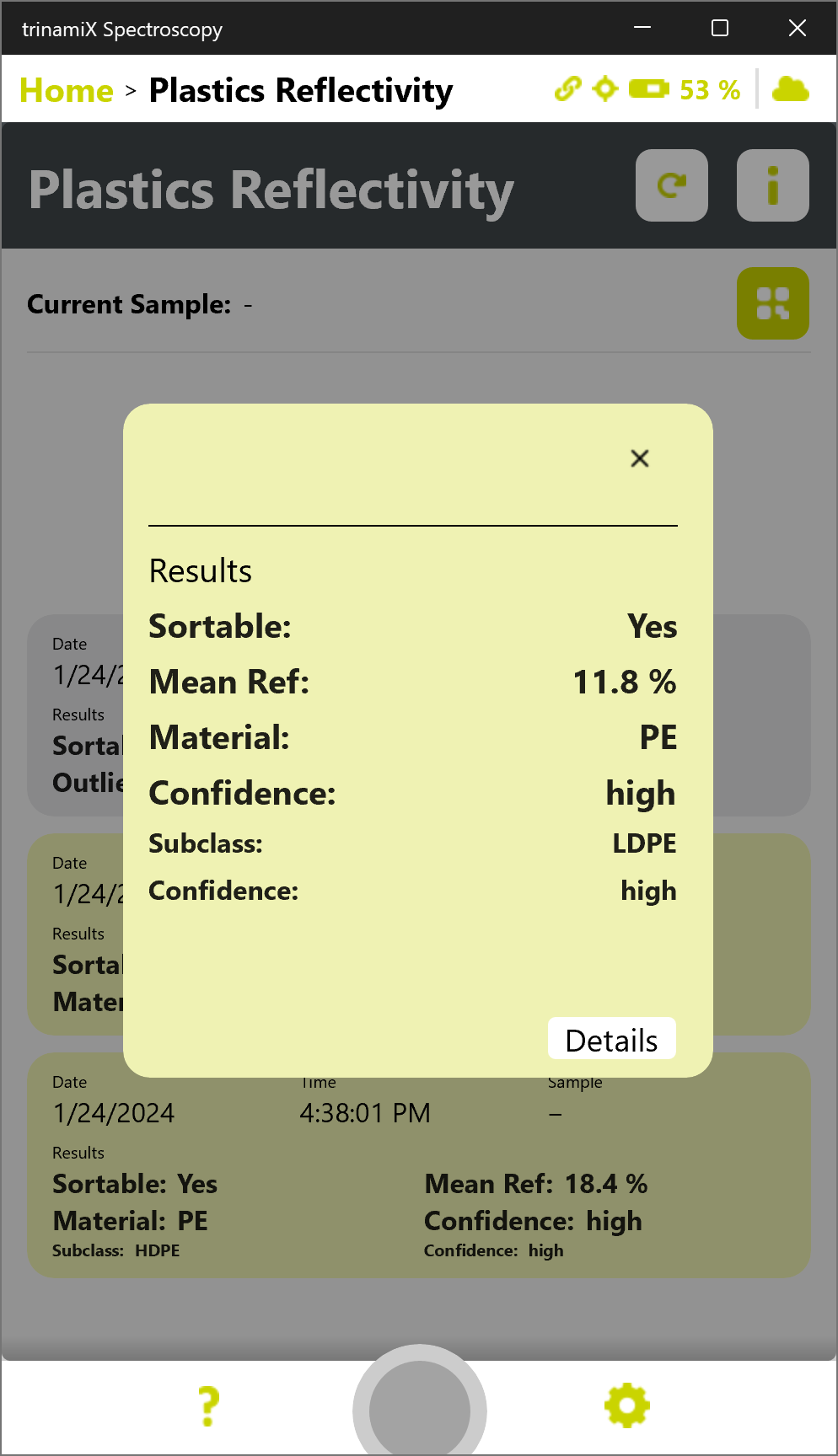

Challenge 2: NIR Detectability During Product Development

For manufacturers of high-performance tapes, NIR detectability is increasingly a design factor — especially for complex multilayer films, coated surfaces, and advanced adhesives. Without proper detection, these materials may fail automated sorting or contaminate recycling streams.

Our Solution

Our mobile NIR spectroscopy system is used by converters and compounders to analyze the detectability of films, liners, and adhesives — even in the early R&D phase. SMEs can check sortability without laboratory infrastructure and make data-driven design decisions.

Why It Matters

Our mobile NIR solution enables tape producers to:

- Work without lab infrastructure – affordable for small teams

- Use proven tools already active in recycling and packaging QA

- Rely on battery-powered, portable scanning tools

- Analyze materials including films, foils, adhesives, and liners

Whether you’re reacting to customer requests, preparing for regulations, or improving sustainability KPIs — you can now test your products in-house and in seconds.

Interested in a Free Sample Analysis?

If you’re exploring how NIR testing could support your R&D, QA, or recycling processes, we’re happy to analyze 1–2 of your samples and walk you through the results.

Contact us:

📧 info@solidscanner.com

About us – Solid Scanner

Let’s take responsibility and recycle more plastics, textiles, carpets, mattresses and more – ask us for suitable solutions. Our portfolio includes solutions ranging from small, portable solutions to individual solutions based on hyperspectral camera systems for simple, automated identification of plastics and in the sorting process and for inline process control, e.g. for homogeneity.

About trinamiX – the sensor technology company

Our technology partner trinamiX GmbH, based in Ludwigshafen, was founded in 2015 as a wholly owned subsidiary of BASF SE. As a start-up within the company, it is not only operationally independent, but also has unique access to the expertise and experience of the entire BASF Group. Its patent-pending technologies enable people and machines to capture the hidden and invisible world around them to make better decisions and increase safety.