Why PA6 / PA6.6 Differentiation Matters in Circular Textile Recycling

PA6 and PA6.6 are widely used in textile applications and are visually similar. When mixed, they complicate downstream processing and material routing.

Being able to distinguish between these two polyamides at the point of sorting is therefore a practical requirement in textile-focused recycling workflows.

Industrial Context: PA6 / PA6.6 Separation as an Enabler for Textile Recycling

In January 2024, BASF published a press release describing the importance of separating PA6 and PA6.6 within textile recycling initiatives. This communication reflects broader industry intent to address polyamide complexity in circular systems.

The reference provides context for why PA6 / PA6.6 differentiation is relevant. It does not validate, endorse, or certify any specific device or measurement approach described below.

What Is Demonstrated in This Example

This post documents a demonstration of PA6 / PA6.6 differentiation using a portable near-infrared (NIR) system from trinamiX.

The example focuses on:

- Textile materials

- A dedicated PA6 / PA6.6 application

- Handheld, operator-level use via a smartphone interface

The intent is to show what the system outputs look like in practice, not to claim universal performance or guaranteed outcomes.

Operator-Facing Output: PA6 / PA6.6 Identification in Practice

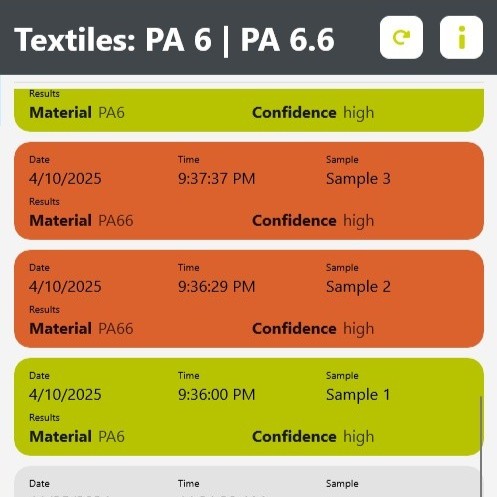

Textile PA6 / PA6.6 App – Operator View

Operator-facing classification output from the Textile PA6 / PA6.6 app.

Confidence level shown as reported by the app.

Inconclusive state indicated when classification confidence is insufficient.

These screenshots represent what an operator sees during scanning. No interpretation beyond the displayed classification and confidence indication is implied.

Representative Spectral Data (Exported Example)

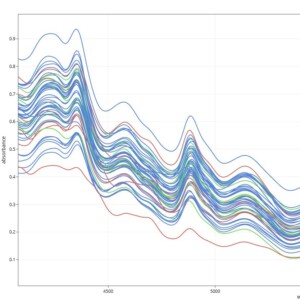

Representative spectral data exported from the system during PA6 / PA6.6 scanning.

Representative example, not a complete dataset.

The data shown is an excerpt of exported measurements. It is included to illustrate the type of raw output generated by the system.

Download here an example of raw spectral output as provided via XLS export.

Example Report Output (Anonymized)

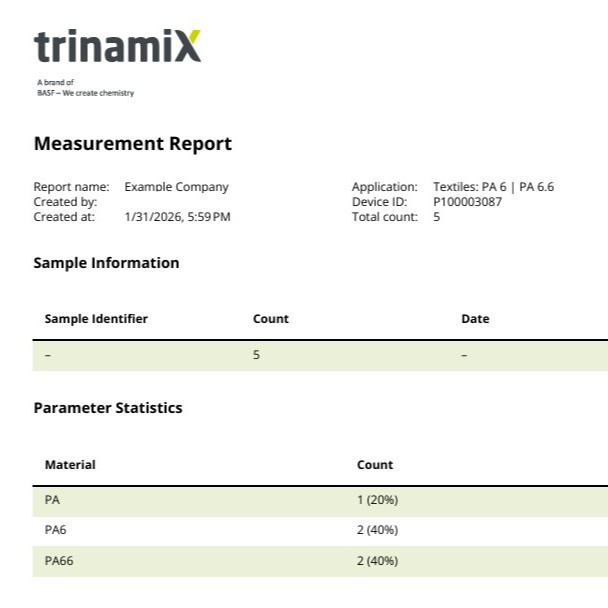

PDF report excerpt illustrating recorded scan outcomes. Report exported from the customer portal following PA6 / PA6.6 scans.

Report structure shown without performance interpretation.

The report excerpts demonstrate how scan results can be recorded and exported for documentation purposes.

- Download Single Measurement Report here.

- Download Multi Measurement Report here.

How These Outputs Are Used During Sorting

During operation, the handheld scanner and app provide immediate classification feedback to the operator. The output supports decision-making at the sorting stage, where materials may be routed, set aside, or flagged for further review.

Exported spectral data and reports allow results to be stored and reviewed outside the scanning moment. These outputs complement operator judgment rather than replacing it.

Scope and Limitations of This Demonstration

This example represents a demonstration, not a universal guarantee of separability.

Results depend on factors including:

- Material condition

- Surface state

- Coatings, blends, or contamination

Inconclusive results are possible and are indicated as such by the system. The outputs shown here should be interpreted within this limited scope only.

Relation to Broader Textile Recycling Initiatives

PA6 / PA6.6 differentiation is one element within wider textile recycling efforts, including initiatives such as loopamid. The demonstration shown here addresses a specific operational step without implying system-level conclusions.

Seeing the System in Operation

For those evaluating applicability to their own textile material streams:

- Request a live demonstration

- Discuss how the system may behave with specific materials or conditions